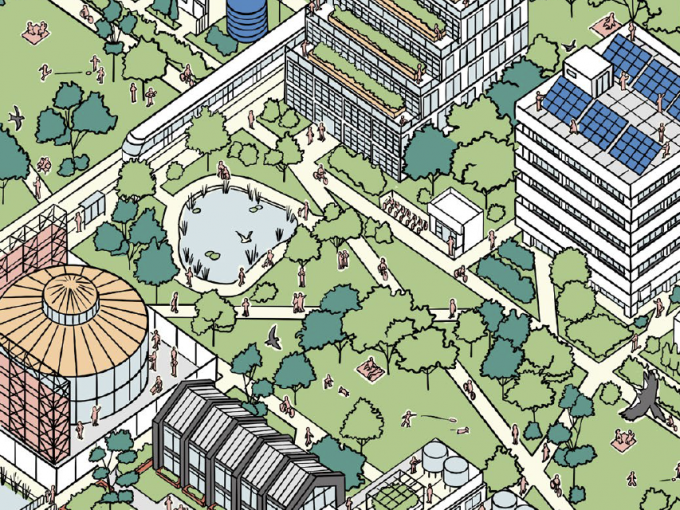

On May 10, 2023 the World Green Building Council (WGBC) and its global network launched the Circular Built Environment Playbook — a guide for the building and construction sector to accelerate the adoption of circular economy and resource efficiency principles. This builds upon a series of reports by the Sustainable Buildings and Construction programme (part of UN’s One Planet Network) on circular economy and the built environment.

A circular economy calls for closed loop material flows that minimise environmental burdens while also delivering social and intergenerational equity, local economic opportunities, and resource efficiency. The WGBC defines circular economy principles as:

- Reduction in consumption of materials and resources

- Optimisation of lifespan for materials and product use

- Design for disassembly, reuse and recycling, and the elimination of all waste

- Regeneration of nature

The paradigm of circular economy also calls for measures that reduce the embodied carbon in new manufactured materials used to construct new buildings and maintain existing buildings.

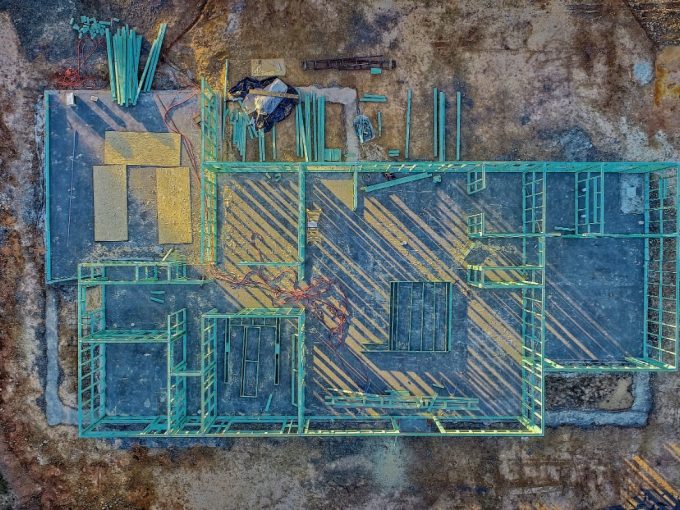

Construction and demolition waste (CDW) is closely related to continued urban growth. Buildings typically have a construction, retrofit, demolition and redevelopment life cycle, and each of these stages produce CDW. In Australia, approximately 29m tonnes of CDW per annum is created, which constitutes approximately 38 per cent of all waste. Of this, approximately 22.4m tonnes is recycled into road base (77 per cent) and 6.4 tonnes goes to landfill (National Waste Report 2022). CDW is also growing rapidly – the quantity of CDW per capita has grown by 32 per cent over the last 13 years.

There is significant untapped potential to embrace circularity in the material market and the broader industry that delivers housing in Australia. Materials extracted during demolition or renovation still have high value and are often either reusable or recyclable into new construction materials. Reusing materials can help reduce the carbon footprint of resource extracting, and repurposing existing building parts or products can lead to important cost-savings.

Yet circularity for materials (such as reusing, recycling and repurposing) is currently limited in the residential sector in Australia by practices, and by a lack of regulatory framework and suitable business models. The building and construction industry needs support to shift practice towards closing material loops.

Our recently completed AHURI funded research found that through circular economy principles the housing industry and its supply chains could contribute to decarbonising the housing stock by using low carbon materials and relying less on virgin materials.

We conducted supply chain modelling, interviewed key stakeholders in material supply chains and researched residential developments with low carbon design and procurement objectives. Based on our findings, here are six actions we can take to accelerate material circularity for housing:

1.Improve material stocks and flows tracking and data systems throughout the residential construction sector

Improved understanding of material flows is important for increasing circularity in the industry. This applies to both new materials and materials in the existing housing stock materials as they will become future CDW streams. The Commonwealth Scientific and Industrial Research Organisation (CSIRO) has made considerable progress in the development of a data system with its Australian Housing Data Portalcollecting data on new housing since 2016. However, further initiatives such as compulsory “as-built documentation” (ABD), and “material passports” would improve stock in-use and materials tracking. All materials data should be geocoded so as to support regional and local analysis of material flows.

2. Regulate and incentivise for good design, disassembly and material reuse

Good design should consider materials use and end of life disassembly and reuse. Currently building industry participants struggle to justify planning for disassembly and materials reuse. Policy development should incentivise and require disassembly and reuse, and materials selection and local product use that reduces the embodied energy in buildings. As well as incentivising disassembly and reuse, we could also discourage materials going to landfill (e.g., through increased financial costs, making consumers/clients aware of cost-savings that can be made from reuse/repurpose).

Measures such as the provision of spaces to store materials for reuse and regulations from state environmental protection agencies support the safe stock piling of used materials. Creating markets for materials reuse within Australia is important, but as many materials and products are imbricated in global supply chains, it is likely that they will have to also be supported by border adjustment policies. It is important that all domestic building-industry participants are encouraged to participate in markets that minimise and value CDW and materials reuse.

3. Factor in the embodied carbon created by material manufacture in sourcing materials from suppliers

The National Construction Code (NCC) should be revised to extend its focus beyond operational energy to include energy used to manufacture building materials and construct buildings. This can be done by requiring the recording of embodied carbon in material flows and construction and demolition waste reuse. This regulation could be supported by a simple-to-use digital recording system that records the flow of materials into and out of the housing system. Most recycling and reuse regulation focuses on end-of-pipe solutions. They should be revised to support the measurement of material flows and retaining value in materials through reuse, rethinking, repurposing and remanufacture.

4. Low-carbon supply chain councils could support collaboration and decarbonisation of material supply chains

Building materials supply chains involve different actors with different interests. They include manufacturers, distributors, retailers, regulators, professional consultants, contractors, and subcontractors. Low-carbon supply chain councils could be established where the actors collaborate on strategies aimed at decarbonising these supply chains. For example, there could be consideration into how to reuse, repurpose or recycle material off-cuts to loop back throughout the supply chain, as well as strategies to avoid single use plastics in the manufacturing and delivery of products.

Members would be drawn from industry and professional associations, civil society social movement organisations, and relevant unions. The councils, supported by a federal government industry agency, through deliberative consultative processes would prepare practical plans for decarbonising material supply chains.

5. Encourage extending the life of product use by replacing product ownership with sustainability service models

Many building products, such as carpets, lighting, partitions, wall panelling, blinds, curtains, PV panels, kitchens, and batteries, are often renewed multiple times during the life of buildings including housing. There is scope for the development of new ownership models, particularly through leasing, that support maintenance, extending the life of products and waste reduction through, design, material innovation, reuse, and end of life recycling and downcycling.

Prefabricated materials, such as concrete sections in higher-density buildings, can be reused when a building reaches the end of its life. One of the benefits of reusing prefabricated materials is that we tend to know their capabilities and what it could be reused for. This can extend the life of the product by reusing or repurposing the material in a different building, rather than demolishing it. Service models could therefore be extended to parts of buildings that support disassembly and reassembly. Prefabrication plays an important role in this process, particularly when assembly joints are thought through carefully with disassembly in mind.

6. More circular economy experts and leaders for the housing industry

Expanding the pool of people in the housing industry that know about the circular economy is a priority. This will require university and TAFE curriculum development and professional development programs focusing on emissions reduction, circular business models, materials manufacturing supply chains and innovation, and designing and procuring for low carbon construction, maintenance, and deconstruction. SMEs and other stakeholders can also play a key role as they are the ones delivering the outputs for the industry that eventually will get skilled in this area.

These six actions towards reducing emissions from building materials manufacture requires collaborative reform supported by broader public policy. Housing markets cannot meet the challenge without purposeful public intervention and stakeholder co-operation. Simply relying on demand to drive the supply of more circular goods and services does not consider the weakness of consumer voice and nature of current supply chains, in the context where one third of all households rent their homes and have little influence on how the materials that make their homes may or may not be reused and repurposed.

Story by: Louise Dorignon, Usha Iyer-Raniga, Leela Kempton, Trivess Moore, Tillmann Boehme, Tony Dalton and David Oswald.

This article originally appeared on The Fifth Estate and has been republished with permission. Read the original here.